Crafting Secrets Revealed Mastering Sublimation Shrink Sleeves

Sublimation shrink sleeves stand out as a versatile and innovative solution.

Prepare to embark on an exciting journey into the fascinating realm of sublimation shrink sleeves, where creativity knows no bounds and possibilities abound for sublimation crafting enthusiasts like yourself!

Discover the marvel of sublimation shrink sleeves – a heat-resistant material meticulously crafted to envelop your sublimation blank and print. Witness how it magically tightens and conforms with precision when subjected to heat, creating the perfect pressure environment essential for flawless sublimation results.

Disclosure: This post contains affiliate links. I receive a small commission at no cost to you when you make a purchase using my links. As an Amazon Associate, I earn from qualifying purchases.

Mastering the art of crafting sublimation shrink sleeves can significantly elevate your product presentation and brand recognition. In this comprehensive guide, we delve into the intricacies of crafting these sublimation sleeves with finesse and precision.

What Ways Can Sublimation Shrink Sleeves Add Value to Crafted Items?

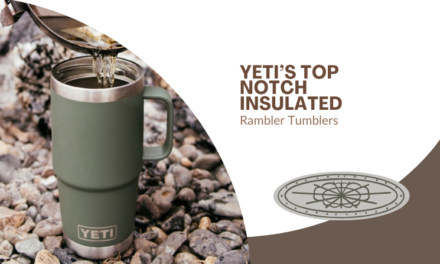

When you’re rocking a tumbler press, heat press, mug press, or any other fancy gadget in your sublimation crafting arsenal, they’re all about applying that perfect pressure to your sublimation print.

No need for shrink sleeves here! But when you’re rolling with a sublimation oven or convection oven for your mugs, tumblers, pens, and whatnot, it’s a different story.

It’s just you, your craft, and some trusty tape holding that sublimation print in place – no pressure, literally! Get excited, because the sublimation shrink sleeve is about to become your crafting bestie!

Deciphering the Perfect Instances of When to Embrace Sublimation Shrink Sleeves

Let’s spice up your crafting journey! Sublimation shrink sleeves take the stage when you’re baking up a storm in your sublimation oven or convection oven. But when you’re flexing your skills with a tumbler press, mug press, or heat press, there’s no need for shrink sleeves – they’re off having a tea party while these presses bring the pressure!

Selecting Quality Materials

The choice of materials significantly impacts the durability and aesthetics of sublimation shrink sleeves. Opting for high-quality substrates ensures vibrant color reproduction and resistance to wear and tear.

Where You Can Purchase Sublimation Shrink Wrap

Once you’ve settled on the size and type you desire, here are a couple of my top picks for sourcing.

Sublimation Shrink Wraps Come In Various Sizes

When acquiring sublimation sleeves, it’s essential to consider their opening orientation. Certain sleeves open on the short side, while others open on the long side. This aspect significantly influences the compatibility of the sleeve with different blank sizes, so choose wisely to ensure a perfect fit for your crafting projects.

Is it possible to utilize a single size shrink sleeve for all your sublimation endeavors?

Well, the answer may not be as straightforward as you’d hope. While it’s true that you can shrink larger sublimation sleeves to accommodate smaller blanks, there’s a caveat to consider. Oversized sublimation sleeves may result in undesirable wrinkles, potentially leading to gaps in pressure during the sublimation process.

For optimal results, it’s recommended to aim for a sublimation shrink wrap sleeve size that closely matches the dimensions of your blank. However, in instances where an exact fit isn’t feasible, opting for a slightly larger sublimation sleeve may still yield satisfactory outcomes.

Selecting Quality Materials

The choice of materials significantly impacts the durability and aesthetics of sublimation shrink sleeves. Opting for high-quality substrates ensures vibrant color reproduction and resistance to wear and tear.

Precision Printing Techniques

Precision printing techniques are crucial for achieving crisp and clear images on sublimation shrink sleeves. Advanced printing technologies, such as digital printing and offset printing, offer superior color accuracy and detail reproduction.

Moreover, employing specialized inks formulated for sublimation ensures optimal results and longevity.

Embracing Customization and Personalization

Customization and personalization are powerful tools for creating memorable and impactful sublimation shrink sleeves.

Tailoring designs to specific target demographics, occasions, or promotions can resonate with consumers on a personal level and drive brand loyalty.

Whether it’s incorporating individualized messages or offering customizable options, embracing personalization adds a touch of exclusivity and relevance to your DIY project.

Secret Tip Behind Shrink Sleeve Melting in the Oven

If you’re experiencing your sublimation shrink sleeve melting in the oven, it’s often indicative of utilizing a shrink sleeve of inferior quality.

These sublimation sleeves come in several sizes and we have experimented with and all work great.

For crafters who prefer the convenience of ordering supplies from Amazon, PYD Life offers an extensive range of top-notch sublimation shrink sleeves. We have personally tested and vetted these brands, and can attest to their durability and performance.

Rest assured, these sleeves are built to withstand the heat of your sublimation oven without melting, ensuring a seamless crafting experience every time.

Mastering the art of crafting sublimation shrink sleeves requires a blend of creativity, expertise, and precision.

By focusing on design excellence, material quality, printing precision, and innovative features, you can elevate your product packaging to new heights and captivate your audience.

Embrace the possibilities of customization, personalization, and interactivity to create immersive brand experiences that leave a lasting impression.