The Power of Sublimation Printing Review our in-depth exploration of sublimation printing, an innovative technique that has revolutionized the world of design and customization.

We will unravel the intricacies of sublimation printing, providing you with a profound understanding of its applications, benefits, and the seamless process behind this cutting-edge printing method.

Disclosure: This post contains affiliate links. I receive a small commission at no cost to you when you make a purchase using my links. As an Amazon Associate, I earn from qualifying purchases.

Understanding Sublimation Printing

What is Sublimation Printing?

Sublimation printing is a unique and advanced printing process that involves the transformation of solid ink into a gas without passing through a liquid phase.

This process utilizes heat and pressure to transfer high-quality, vibrant, and durable images onto various materials, such as textiles, ceramics, and metals.

Sublimation Printing Process

The process begins with a specialized printer using sublimation inks to create a mirrored image on transfer paper.

This paper is then placed on the desired material, and heat and pressure are applied. As the ink turns into a gas, it permeates the material’s fibers, resulting in a permanent, high-resolution image.

Applications of Sublimation Printing

Textile Industry

One of the primary applications of sublimation printing is in the textile industry.

The method is widely employed to produce custom apparel, sportswear, and promotional items.

The prints are not only visually striking but also resistant to fading and wear, ensuring longevity and vibrant color retention.

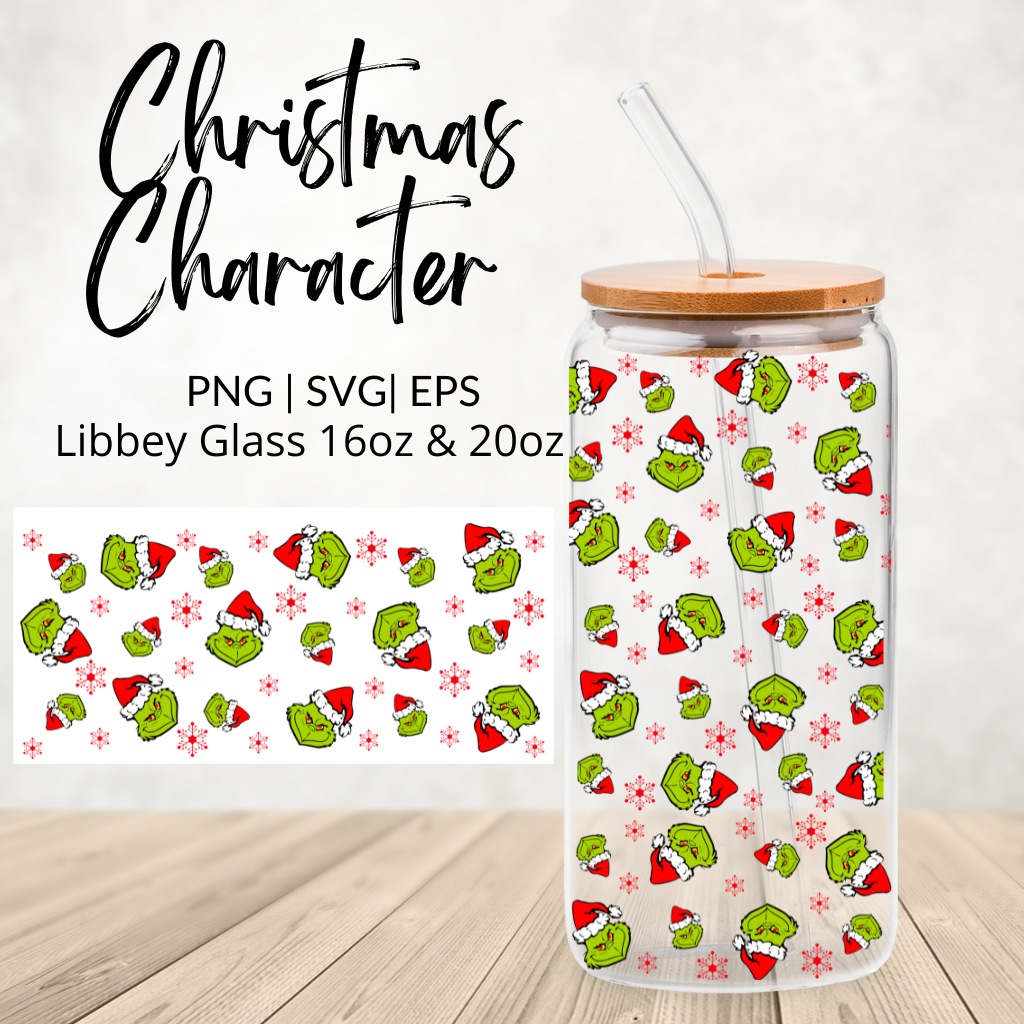

Home Décor and Personalized Items

Sublimation printing has gained popularity in the creation of personalized home décor items.

From custom mugs, tumblers, glassware, decorative pillows to vibrant wall art, the versatility of sublimation allows for the seamless transfer of intricate designs onto a myriad of surfaces, adding a personal touch to everyday items.

Industrial and Promotional Products

The durability and quality of sublimation prints make them ideal for industrial and promotional products.

From creating branded merchandise to industrial labeling, sublimation printing offers a cost-effective and visually appealing solution.

Advantages of Sublimation Printing

Vibrant and Permanent Colors

One of the standout advantages of sublimation printing is its ability to produce vibrant and permanent colors.

The process ensures that the ink becomes a part of the material, resulting in prints that resist fading, cracking, or peeling over time.

Durability and Longevity

Sublimation printing creates durable and long-lasting prints that can withstand regular use and washing.

This makes it an excellent choice for items that require frequent handling or exposure to the elements.

Versatility Across Materials

Gnome New Years Tumbler

20 oz Sublimation Tumbler Wrap – PNG Digital File sublimation gnome tumbler wrap

Sloth Tumbler Wrap

Sloth Valentine Leopard Tumbler Wrap Design. 20 oz. Sublimation Design

Messy Bun Christmas Tumbler

Elevate your holiday moments with our exclusive Messy Bun Christmas Tumbler

Sublimation Printing vs. Traditional Printing

Why Sublimation Printing Stands Out

Superior Image Quality

Sublimation printing surpasses traditional methods in image quality.

The gas-based ink penetration ensures a seamless and high-resolution image transfer, capturing intricate details and nuances with unmatched precision.

Eco-Friendly Approach

Compared to traditional printing, sublimation printing is more environmentally friendly. It eliminates the need for water in the printing process and reduces waste, making it a sustainable choice for businesses and consumers alike.

Getting Started with Sublimation Printing

Essential Equipment and Materials

To embark on your sublimation printing journey, you’ll need a few key components:

Sublimation Printer: Invest in a high-quality printer designed for sublimation printing.

Sublimation Inks: Ensure you use genuine sublimation inks for optimal results.

Transfer Paper: Choose the right transfer paper suitable for your materials.

Heat Press: A reliable heat press is crucial for applying heat and pressure during the transfer process.

Step-by-Step Sublimation Printing

- Design Preparation: Create or select your design using graphic design software.

- Printing: Use the sublimation printer to print the mirrored image on transfer paper.

- Material Preparation: Place the transfer paper on the desired material, ensuring a secure fit.

- Heat Press Application: Employ a heat press to apply the right temperature and pressure for the designated duration.

- Cooling and Finishing: Allow the material to cool before peeling off the transfer paper, revealing the vibrant sublimation print.

Sublimation printing emerges as a game-changer in the world of printing and customization.

Its versatility, durability, and vibrant results set it apart as a preferred choice for industries ranging from textiles to promotional products.

As you delve into the realm of sublimation, explore the endless possibilities it offers for creating personalized and visually stunning items.